Improving the Overall Construction Quality

This page describes general tips and tricks, on how to improve your overall building quality. The following picture galleries show what kind of materials you should look for. They explain how to mix good quality mortars and concrete. They describe how to make your building square, level and plumb. And so on.

If you have further questions, or need assistance with the execution of your building, just send us an email via the contact page.

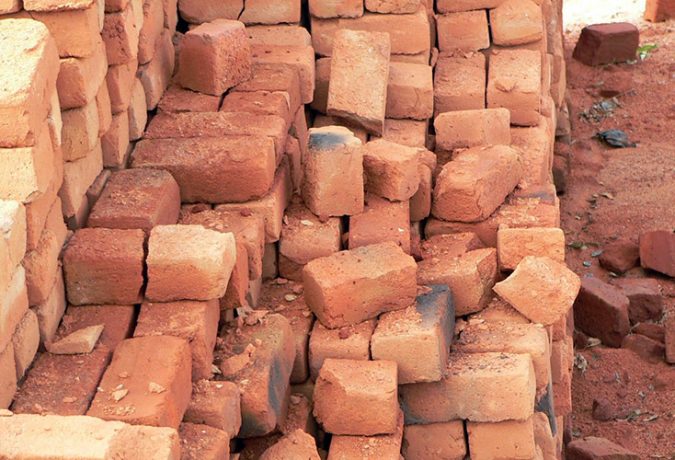

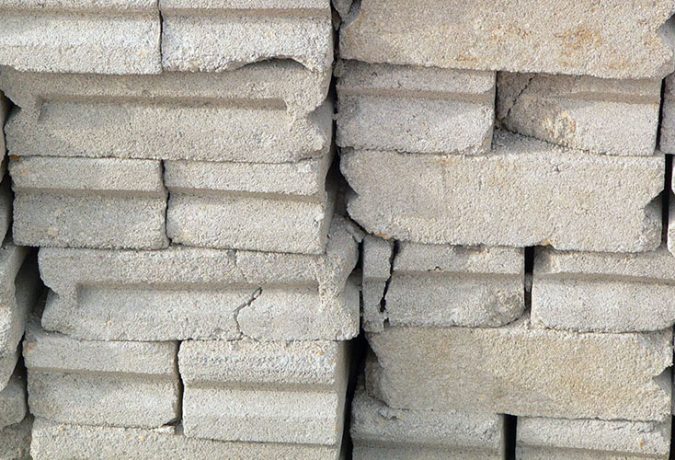

Choosing Good Bricks and Blocks

Full text will follow shortly. For now take a look at the pictures and its captions.

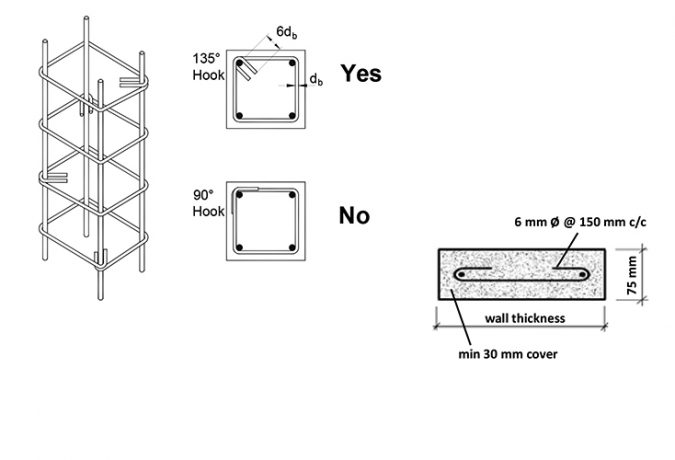

Cement, Steel Reinforcements and Concrete

Full text will follow shortly. For now take a look at the pictures and its captions.

General Improvements on Your Building

Full text will follow shortly. For now take a look at the pictures and its captions.